Our team is made up of Italian leather manufacturers. The products are the result of constant technological research that allows skins to reach the highest quality standards.

Thanks to an uninterrupted dialogue with the contract world, we are able to meet the requests of our customers who want leathers to be used in the fashion, hotellerie and naval sectors.

RAW LEATHER

We are always in contact with the best European slaughterhouses, from which we buy our raw materials, selecting the best quality on the market and paying attention to make sure that we always obtain the largest sizes, which is essential for markets such as furnishing.

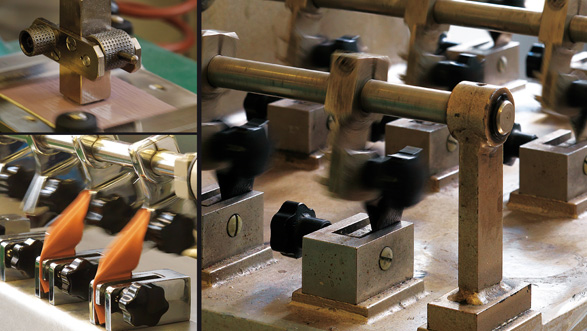

TANNING

Due to our continuous research in tanning techniques, we are able to obtain a high quality and long-lasting product from a sub-product of the food sector. Thanks to the help of our expert staff, through wet blue selection we can direct each and every item of leather to the most suitable article.

DYEING

Once allocated to a certain article, the leather undergoes a new tanning process using grease, tannins and resins in order to ensure that it develops the necessary characteristics. After this, it is dyed in the desired colour using aniline products.

DRYING

During the drying stage, production must take into account the tactile and fullness characteristics that the finished item must have. We use vacuum, frame and Cartigliano techniques.

FINISHING

This is the last stage, and one of the most important, of leather processing. Using pigments and/or anilines, finishing is what gives the leather the desired colour and any special effects.

Cross-linking fixing agents are then used to ensure specific physical-chemical resistance characteristics.

TESTS

The increasing number of requests, particularly from the contract sector, is driving us to find new solutions in order to obtain leather with different characteristics, such as for outdoor use, machine washable, or with more specific features, such as resistance to the most stubborn stains.